The mix is what matters

Article in the WAZ about REICH

Admittedly, there is a world of difference between Coca Cola and Reich couplings: geographically, financially and even the industry are not comparable. And yet the world's best-known brewery manufacturer and the medium-sized company from Bochum have one thing in common: their success is based on a big secret. Just as the Coca-Cola recipe has been guarded for more than 100 years, the rubber element compounds for the flexible couplings are a book with seven seals for REICH. They slumber in a safe.

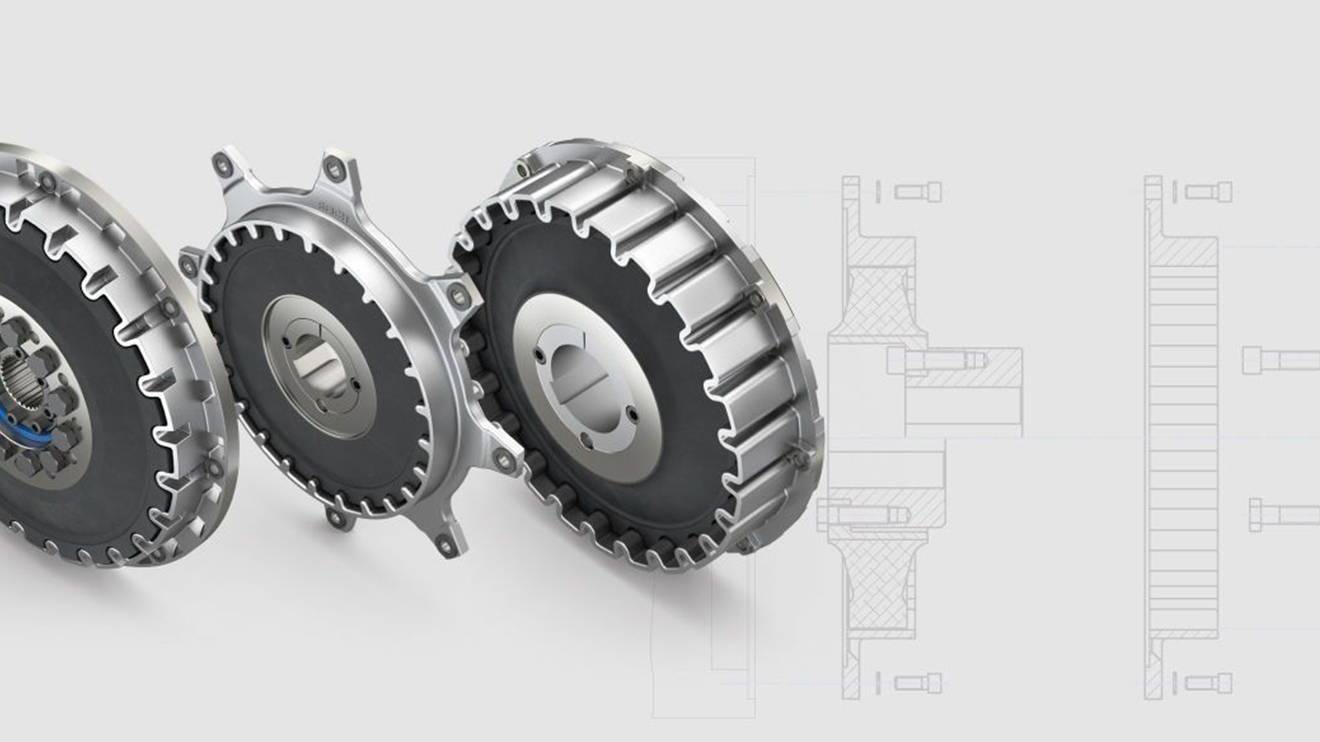

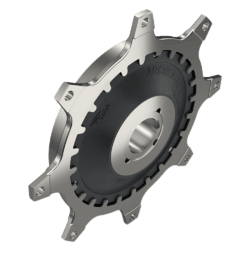

"This rubber is what makes REICH what it is," explains Herwarth Reich, graduate engineer and co-owner of the family business. The metal parts of the couplings, which are also produced in-house, "are standard, others can do that as well," says the senior boss.

Even today, the company's success is still based on rubber compounds that Reich's father developed after the war together with Chemische Werke Hüls. "He had the idea for the flexible coupling," says Herwarth Reich. Numerous patents bear witness to this pioneering work.

Ships, combined heat and power plants, test benches

Although the company founder came from the automotive industry, he worked for Mercedes in Stuttgart. But REICH is only marginally involved in vehicle construction. They are used for the auxiliary drive of functional areas such as concrete mixers or refuse collection vehicles. "In the heyday of truck construction, we delivered 15,000 clutches to Mercedes each year," says Reich. But the products from Grumme are mainly used in industrial production. Whether ships, combined heat and power plants, construction machinery or test benches - they are used wherever power has to be transferred from one engine, usually diesel or gas-powered, to another unit.

The trick here is that since misalignments have to be compensated and vibrations damped in torque transmission, rubber elements in the couplings provide the flexibility and dynamics without which these requirements could not be met. The quality and compounding of the rubber, which is produced by a supplier from natural or synthetic materials according to Reich's formulas, play a major role here.

Especially since "the requirements continue to increase", says junior boss Christian Reich. Whereas 5,000 operating hours used to have to be guaranteed, the industry today demands 20,000 smooth operating hours and more in order to keep maintenance costs and downtimes low. Heat is a major problem here. Natural rubber can "tolerate" temperatures of up to 80 degrees Celsius, while synthetic silicone, which is less flexible, can withstand temperatures of up to 130 degrees. Blends of these and other rubber types make it possible to meet specific requirements.

This is one of the reasons why research and development play a major role in keeping ahead of the competition. 30 of the 150 employees in Bochum alone work in this area, and two new two-million-euro test rigs will soon be delivered, which will be used primarily in development.

Production of small series

Especially since Reich does not manufacture mass products but small series that are specially tailored to the customer. "D2C" means in-house, "Designed to Customer", in other words, developed for the customer. It is this pronounced customer orientation and flexibility, according to Herwarth Reich, that makes up the strength of the medium-sized company.

Parts can be shipped all over the world within 24 hours, and the family-owned company has long been represented around the world - either with its own agencies, as in the USA, for example, or through contractual partners. In May, sales experts from 22 countries attended the meeting on Vierhausstrasse, which Reich hosts every two years.

When the father and his son ...

As the father so the son. That's the way it is with the Reichs. Both Herwarth Reich and Christian Reich studied mechanical engineering in Aachen, both have a diploma in engineering. And both are in charge of the company - the senior even more so than the junior. Sooner or later the balance will shift. "I can easily do without the daily routine in the company," says Herwarth Reich (65), who is attached to the family business but not stuck in his armchair. For a year now, he has been preparing his son to take over responsibility. One of the maxims: "The employees are our greatest jewel. That's what I try to pass on to the third generation."

Of course it was not that Christian Reich followed in his father's footsteps. He earned his first professional laurels elsewhere. He worked for three years at BMW in Munich before returning to Bochum and joining the family business.

Challenging task

"He surprised my wife and me after his school-leaving examination by enrolling in Aachen," says the senior boss. He did not feel urged to do so, says the junior boss. "I grew into it like that from an early age." And why has he returned from Munich? "To develop the company further.

Link / source: http://www.derwesten.de/

Post details:

If you have any questions about this article, use our or simply call: +49 (0)234 959160