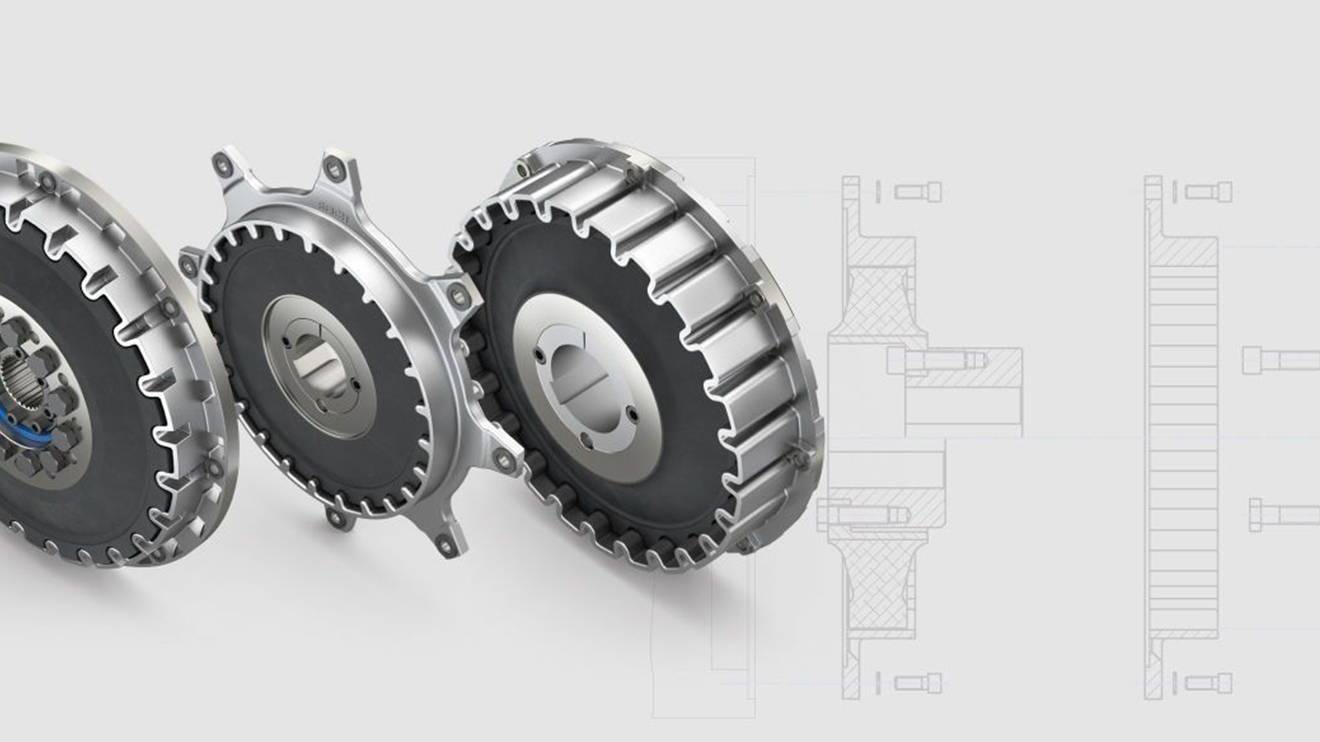

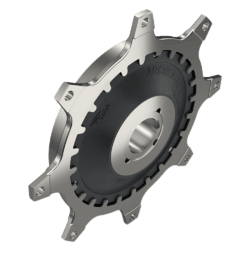

New ‘Y’ Elastomer Increases the Service Life of the Proven Arcusaflex Coupling by 7-Times

Successful Initial Use in a Combined Heat and Power Plant: Highly Stress Resistant 'Y' Rubber Compound from REICH Increases the Life of Arcusaflex Couplings in Thermally Critical Applications.

REICH has usually employed silicone rubber for highly flexible power transmission components to be used at high temperatures. This silicone rubber type is listed as 'X' compound and suitable for temperatures up to +120 °C, or in some cases up to +130 °C. This material, however, has limited mechanical properties and tends to heat up additionally under extreme conditions including operation close to resonance speed. This can lead to earlier-than-expected overloads and failures.

This is why the 'Y' rubber compound has been developed for high temperatures and specific operating conditions. The 'Y' elastomer is extraordinarily heat-resistant and can be used at service temperatures from –25 °C to +120 °C.

The new 'Y' elastomer was employed for the first time in 2014 in a combined heat and power (CHP) plant of a central purification plant where an Arcusaflex coupling with a standard elastomer made of natural/synthetic rubber compound had originally been in use ‑ the right choice for a temperature range from –40 °C to +80 °C. But the temperatures occurring directly at the coupling were actually higher, last but not least due to the specific mode of operation of the CHP plant, so that initial incipient cracks began to show in the rubber disc coupling after just 3,000 hours of operation. The coupling failed after approximately 4,500 hours of operation and had to be replaced by another element.

The desired coupling life is typically 20,000 hours of operation. The proven ARCUSAFLEX® couplings from the Bochum-located coupling manufacturer are quite capable of providing 35,000 hours of operation and more – depending on the ambient conditions such as the temperature in the mounting space, the level of contamination, the presence of chemicals, etc.

Highly Resistant to Heat, UV Light, Ozone and Aggressive Substances

When, however, premature incipient material cracks began to show again after the coupling had been replaced, Reich Kupplungen started to investigate the cause. The problem: The temperatures turned out to be distinctly above +80 ºC, contrary to what had been stated previously. The solution: The use of the new 'Y' rubber compound.

This material features excellent durability against high temperatures, UV light, ozone and aggressive substances such as chemicals, hot water and steam. As regards its durability against oils and fuels, it is comparable to that of the common natural/synthetic rubber compounds. Thanks to its good strength properties even at elevated temperatures, the rubber compound is suitable for highly flexible designs which are subjected to pressure and shear stresses.

'Y' Elastomer Has Proven Its Worth in Thermally Critically Applications

The decision to go for the 'Y' elastomer has proved to be successful. The coupling, having completed 31,000 hours of operation since its start-up, is still working properly: No cracks, no failures, and only with initial signs of abrasion on the toothing. This way the service life could be increased by at least seven times.

Since that time, some hundred couplings featuring the new elastomer have been successfully put into operation in the most diverse and often thermally critical applications - whether in compressors in the desert, in crushers with extreme shock loads or generator sets with a minimum mounting length. Here again, the service lives of these couplings could be improved by a multiple of times through the use of the 'Y' compound.

REICH is a highly specialised company in the field of power transmission. Their focus is on the development and manufacture of torsionally flexible and torsionally rigid coupling series with a high degree of vertical integration. These processes are basically accomplished in-house so that high competence in the design and manufacture of couplings is ensured for the respective power transmission applications.

Image source: REICH

Post details:

If you have any questions about this article, use our or simply call: +49 (0)234 959160