Coupling system for methanol hybrid drive

First electric excursion vessel in Germany with methanol hybrid drive and Reich-Kupplungen coupling system.

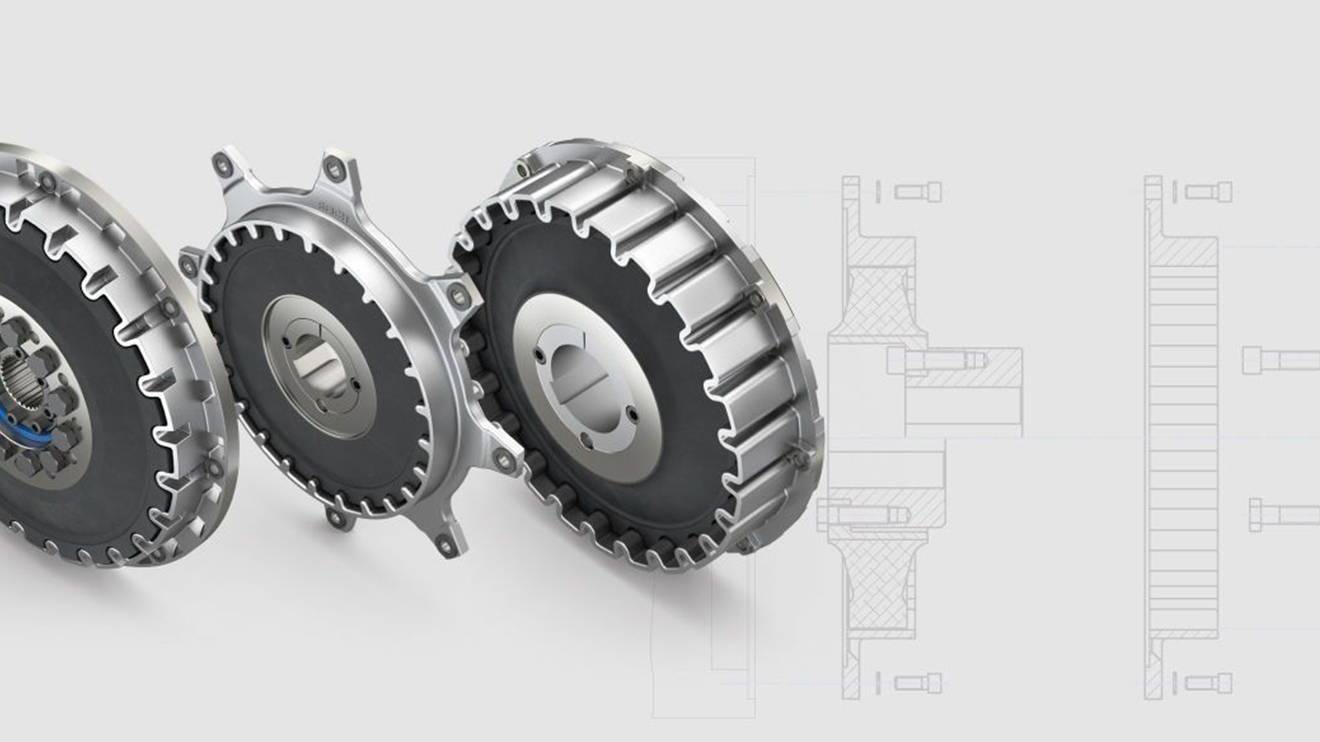

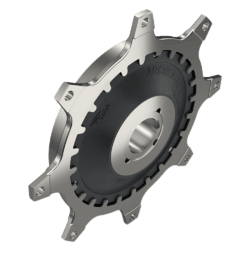

Germany’s first electrically driven excursion vessel has been fascinating the regular and charter guests on the Baldeney Lake in Essen since 25 August 2017. Its low noise performance and eco-friendliness is due to the vessel’s combination of methanol tank, fuel cell and motor. The coupling system for the drive has been developed and delivered by the company REICH. The complete coupling unit consists of the MULTI MONT SELLA claw coupling, the ARCUSAFLEX® flange coupling and two electromagnetic clutches.

Germany’s first electrically driven excursion vessel has been fascinating the regular and charter guests on the Baldeney Lake in Essen since 25 August 2017. Its low noise performance and eco-friendliness is due to the vessel’s combination of methanol tank, fuel cell and motor. The coupling system for the drive has been developed and delivered by the company REICH. The complete coupling unit consists of the MULTI MONT SELLA claw coupling, the ARCUSAFLEX® flange coupling and two electromagnetic clutches.

The engineers of the Bochum-based coupling manufacturer faced the challenge of delivering a switchable propulsion drive system which allows the automated use of the three drive types: purely electric drive, pure diesel drive or combined diesel-electric drive. To reduce the occurring vibrations of the engine, the motor and the drive components, flexible and highly-flexible couplings are combined with the electromagnetic clutches and integrated into a compact housing to form a compact unit.

The coupling unit was installed in an existing passenger vessel as part of the methanol hybrid drive. The conversion took place in the context of “European Green Capital – Essen 2017”. Here, you can see different examples from the city of Essen for how changing the climate policy towards eco-friendly energy sources may look like – on land and on water.

Climate-friendly technology

Especially the shipping industry is still characterised by the exhaust gases and the noise of conventional diesel engines. But the future lies in clean fuels. The new addition to Baldeney Lake is the first vessel in Germany with a motor powered by an eco-friendly methanol fuel cell.

The energy required for operation is generated entirely from renewable energy sources. The energy source ethanol is created by a run-of-river power station located directly at the dam of Baldeney Lake. Carbon dioxide for the electro-biocatalytic methanol production is filtered from the ambient air by means of a container. Using hydroelectric power, the enzymes are stimulated to convert water and carbon dioxide into methanol.

But the amount of methanol gained daily is not enough. This is why additional methanol, also produced in an eco-friendly manner, is bought from Iceland. 330 litres of methanol, which supply enough energy for 16 hours, are then used to generate electricity in the 35-kilowatt fuel cell of the vessel to power the vessel’s electrical system and the battery-powered motor.

The two batteries with a capacity of 50 kilowatt hours each last for four hours in total. Afterwards, they need to be recharged by the fuel cell – or by using a charging cable onshore. In case of an emergency, an additional diesel engine is used.

This is how the methanol hybrid drive works:

- The hydroelectric power station at Baldeney Lake filters carbon dioxide from the air.

- Using electricity and water, the carbon dioxide is converted to methanol, a bioalcohol. Methanol can be stored, transported and filled in just like petrol.

- On board the vessel, the fuel cell uses the methanol to generate electricity and to supply it to the battery-powered motor.

- During voyage, the vessel’s motor only emits as much carbon dioxide as was originally filtered from the ambient air for the methanol production.

- In an emergency, the diesel engine can be activated via the intelligently designed coupling system to charge the battery via the generator as well as to power the propeller directly.

Visit us at SMM, the world's leading trade fair for the maritime industry in Hamburg from September 4th to 7th, 2018. You will find us in hall A3, booth 327

Image source:

REICH, Photo „RK_Ausflugsschiff_Baldeneysee_Schiff_©_Peter_Prengel_Stadt_Essen.jpg“: Peter Prengel, City of Essen

Post details:

If you have any questions about this article, use our or simply call: +49 (0)234 959160